ALUMINIUM PROFILES

O&P offers premium aluminium profiles, designed for both durability and aesthetics. Customizable to various applications, we ensure each profile meets our client's specific needs.

Standard

aluminium profiles

Special

aluminium profiles

Our advantages are:

We supply aluminum profiles with a maximum circumscribed circle of roughly 390mm, crafted from alloys such as 6060, 6063, 6005A, 6082, and 1050A. Production is in accordance with the approved technical documentation.

We collaborate with clients to determine the final dimensions and tolerances, ensuring agreement on both general and specific functional tolerances relevant to each aluminum profile.

Products from diverse alloys, varied heat treatment.

Non-standard length of aluminium products;

Various colors powder coating on a RAL scale;

Industries we deliver

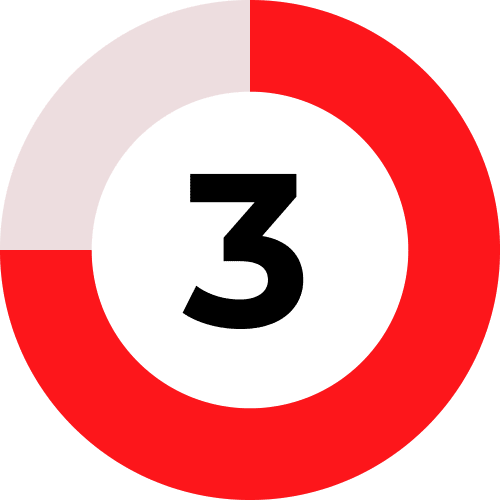

At O&P, we provide aluminium profiles that cater to a broad spectrum of industries. Dominating our portfolio, 38% of our profiles bolster the architectural and construction sectors, while 24% are crafted to customer specifications, offering bespoke solutions.

Our profiles enhance the structural and design elements of interiors (9%) and furniture (8%), and are integral to consumer goods (6%). Additionally, our materials support the electro-technical (5%), mechanical engineering, and engineering networks (3% each), as well as the transport and advertising sectors (2% each).

Across all these fields, we're committed to delivering aluminium profiles that elevate industry standards.

O&P: As a renowned company with a strong position in the European market, we commit to providing services that exceed our clients' expectations.

Our focus on high-quality products and services is a key element of our business.

How we work

Collecting the necessary technical information, defining goals, securing resources.

Design

Technical design, quotation.

Document

Mass production with emphasis on the efficiency of the production line.

Production

Quick and efficient delivery of aluminium profiles.

Delivery

Anodising

Automated line for aluminum anodizing

Provides high production and quality.

Reduces losses due to automatic control.

Reduces line control losses.Optimizes the process of chemical reagents dosing.

Increases production capacity to its maximum due to set parameters and control of the production process in accordance to the customer’s requirements.

Implements the constant registration of data enabling continuous tracing of technological parameters and failures.

Dyeing

Horizontal painting line with an automatic spray camera and quick color change within 15 minutes

Vertical painting complex.

Powder coated goods of any color under RAL color card using high-quality materials offered by the world leaders of the paint and coating industry.

Horizontal painting line.

Mechanical processing

Emmegi and Elumatec CNC processing and sawing centers.

Wide range of sawing, milling, drilling, and perforating equipment.